Releasing Time: 2023.12.28

New Feature:

- Recycle the HACIS warehouse in ufwms site for rent it to HACIS

1.HACIS站点登录时,会经过mfa验证,如图所示

2.HACIS站点只能搜索出HAC开通的customer

3.HACIS站点没有任何的背景数据

Releasing Time: 2023.12.28

New Feature:

1.HACIS站点登录时,会经过mfa验证,如图所示

2.HACIS站点只能搜索出HAC开通的customer

3.HACIS站点没有任何的背景数据

Releasing Time: 2024.01.18

New Feature:

当用户设置扫描serialNo的配置时(wms跟wos都设置),当入库时,选择mode为eceive and Put Away’,系统会提示”Please select ‘Receive first,then put away’/请选择‘先收货,后上架’模式进行操作。

1.当OP出库的时候扫描的serialNo不是系统分配的库存,Picking done/Packing done的时候,系统会更新picklist的serialNo为实际扫描的serialNo.

并且当order被confirm之后,系统会扣减实际出库的serialNo库存,保证库存内的serialNo是准确的。

注:如果实际扫描的SN在库存中没有对应的记录,系统会提示联系supporter进行数据修复。

2.当OP去report模块打印shimadzu的inventory report,系统打印出的inventory report中的SN是真实准确的。

3.当使用ROC进行收货时,系统会记录真实扫描的serialNo,收货完成后在WOS首页使用partNo或者location的barcode去搜索,系统会显示出正确serialNo。

注:本版本发布之后,使用ROC新入库的part能在WOS首页用barcode scan搜索,显示准确的serialNo。对于发布前入库的part,以及使用WOS入库的part,则需要打印inventory report去查看准确的serialNo。

此story目前只配置了UFHYL一个仓库去应用。

1.当进入到WOS4,在查看Task Summary时

可以看到:

1.Ready to Ship (Packed) 包裹待分派状态的订单统计数量

2.Ready to Ship (Sorting) 包裹分派中状态的订单统计数量

3.Ready to Ship (Sorted) 包裹已分派状态的订单统计数量

当点击以上分类订单状态的跳转链接

可以跳转至Outbound Order搜索状态为相应的页面

2.【Outbound—>Order Search status搜索框新增状态】

当用户在Wos4的Outbound页面搜索订单,

可以看到状态搜索框新增Ready to Ship (Packed),Ready to Ship (Sorting) ,Ready to Ship (Sorted)的状态供op选择;

当在状态搜索框搜索Ready to Ship (Packed)/Ready to Ship (Sorting) /Ready to Ship (Sorted)状态,

系统将所有为Ready to Ship (Packed)/Ready to Ship (Sorting) /Ready to Ship (Sorted)状态的订单查询出并按时间倒序显示;

当搜索状态为ready to ship状态的单时,会将Ready to Ship (Packed)/Ready to Ship (Sorting) /Ready to Ship (Sorted)都搜索出来

3.在create shipping Job 界面,status 由ready to ship改为Ready to Ship (Packed)(注:表示已经pack done,未进行sorting的单)

4.进入shipping Job,该shipping Job里的order status会变成Ready to Ship(Sorting);当shippingJob状态变成sorted,该shippingJob的order状态会变成Ready to Ship (Sorted)

1.sort to ship模块新增shipment list页面,OP可以根据条件搜索对应的shipment,例如根据shipmentId,palletId,shipment status,shipment mode,创建人,创建时间等条件进行搜索。

2.系统支持通过双击shipment list中的shipment,跳转到Arrange Shipment页面查看shipment detail

并且允许添加包裹/删除包裹/修改shipment info,shipment list页面会更新并显示最新的数据。

注:只有In processing的shipment才能双击跳转后更新detail,shipped状态的shipment双击跳转后只能查看detail数据不能更新。

3.系统支持在shipment list页面搜索出shipment并批量生成manifest,且对于MUJI,同一个courier service的manifest会合并在一起。

注:当courier不是MUJI的情况下,manifest是根据courier进行合并。

4.系统支持在shipment list页面搜索出shipment并批量confirm In Processing状态的shipment。

1.System offer the Ship Mode:Courier for Print SF label

2.Search the closed pallet in the arrange shipment.The system should load the background setting Shipper and Consignee info as default Shipper and Consignee to generate shipping label for shipment

And the user can change it if necessary

3.The user can select printer to print shipping label for shipment

4.By default, 1 <= Pkg Qty <= quantity of package of the shipment . Support user to change it. (Current system max support print 20 labels,if over 20 ,will remind message)

5.When user try print shipping label for MUJI store pickup shipment

Then

(1) If the system haven’t generate label for the shipment before,

Then the system should generate 顺丰子母单 for the shipment, and print to the selected printer.

(2) if the system have generated label for the shipment before, but the info(Packages, Shipper, Consignee) under the shipment don’t change,Then should printer the generated label for the shipment to selected printer.

(3)if the system have generated label for the shipment before, And the info(Packages, Shipper, Consignee) under the shipment have change,Then should re-generate label for the shipment and print to the selected pritner.

订单状态为Ready to Ship(Packed),才能在sort to ship模块继续操作,非Ready to ship(Packed)状态的订单操作sort to ship会提示Failed, SO-xxxxx is in ‘@SO status’ status and not in ‘Ready to Ship’ status./ 失败,SO-xxxxx处于“@SO状态”状态,而不是“待运送”状态。”

remark:

1.此操作指的是扫描courierBillNo

2.Ready to ship(Packed)指的是在packing模块,完成打包。

【Packing】

OP在Packing操作完Outbound Order后

该订单的状态变为Ready to Ship,并且标有Packed Flag

【Sort to Ship_Arrange Pallet】

仓库OP进入WOS4做Sort to Ship_Arrange Pallet操作

1.OP在Sort to Ship操作Outbound Order订单内的包裹与Pallet进行绑定

Pallet的状态是”In Processing”

那么该Outbound Order的状态为Ready to Ship,并且标有Sorting Flag

2.OP在Sort to Ship操作Outbound Order订单内的部分包裹与Pallet进行绑定

Pallet的状态是”Closed”

那么该Outbound Order的状态为Ready to Ship,并且标有Sorting Flag

3.OP在Sort to Ship操作Outbound Order订单内的所有包裹与Pallet进行绑定

Pallet的状态是”Closed”

那么该Outbound Order的状态为Ready to Ship,并且标有Sorted Flag

当 OP在Sort to Ship_Arrange Pallet模块中操作,将Outbound Order的包裹从pallet上remove

并且该Outbound Order内没有包裹与Pallet相绑定

那么该订单的状态变为Ready to Ship,并且标有Packed Flag

(只要Outbound Order内有一个包裹与pallet相绑定,则Outbound Order的状态为Ready to Ship,并且标有Sorting Flag)

注:1.系统不能允许相同的Package放到多个pallet上

2.Pallet上只能接收最新的快递单号

【首页Task Summary新增订单统计】

OP已经进入到WOS4

查看Task Summary时

可以在Outbound Ready to Ship的下面看到:

1.Ready to Ship 所有ready to ship状态的订单统计数量

2.Ready to Ship + Packed 包裹待分派状态的订单统计数量

3.Ready to Ship + Sorting 包裹分派中状态的订单统计数量

4.Ready to Ship + Sorted 包裹已分派状态的订单统计数量当 OP点击以上分类订单状态的跳转链接

系统可跳转至Outbound Order搜索状态为相应订单的页面

【Outbound—>Order Search status搜索框新增状态】

当OP在Wos4的Outbound页面搜索订单

状态搜索框新增Ready to Ship + Packed,Ready to Ship + Sorting,Ready to Ship + Sorted的状态供op选择

当 OP在状态搜索框搜索Ready to Ship/Ready to Ship + Packed / Ready to Ship + Sorting / Ready to Ship + Sorted状态

系统将所有为Ready to Ship/Ready to Ship + Packed / Ready to Ship + Sorting / Ready to Ship + Sorted状态的订单查询出来

Releasing Time: 2023.12.05

New Feature:

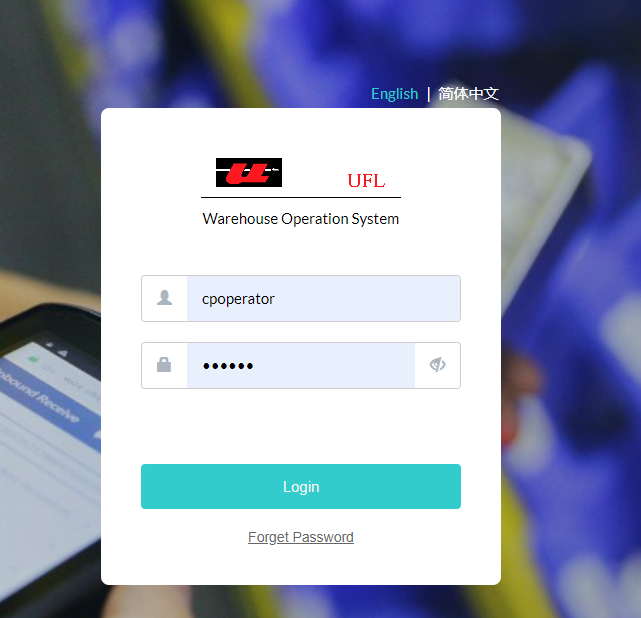

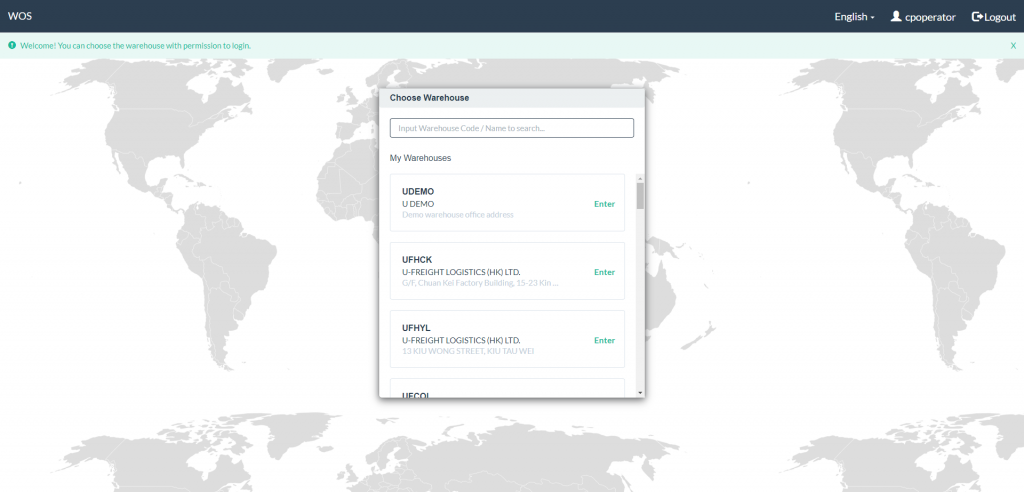

wos4 will adopt a new login interface, as shown below.

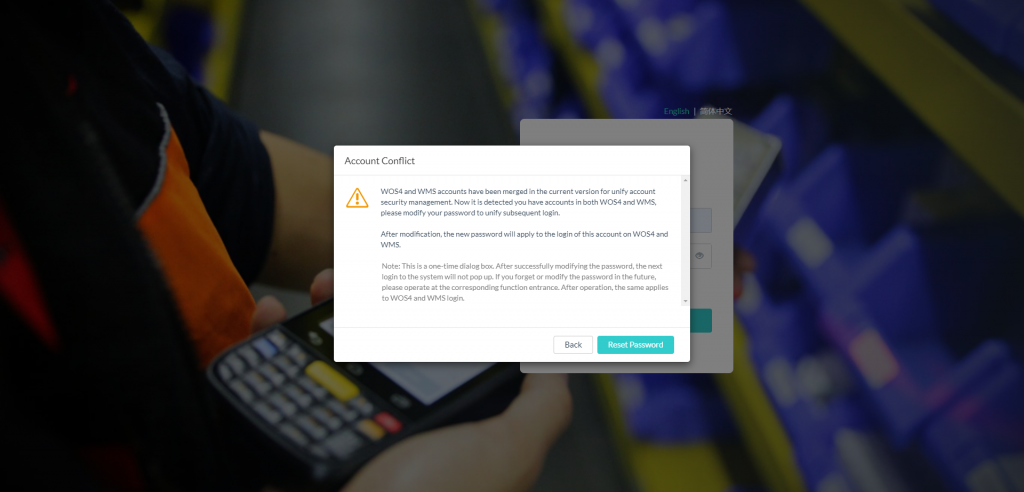

We have synchronized the existing accounts of wos4. When logging in, you will encounter the following two situations:

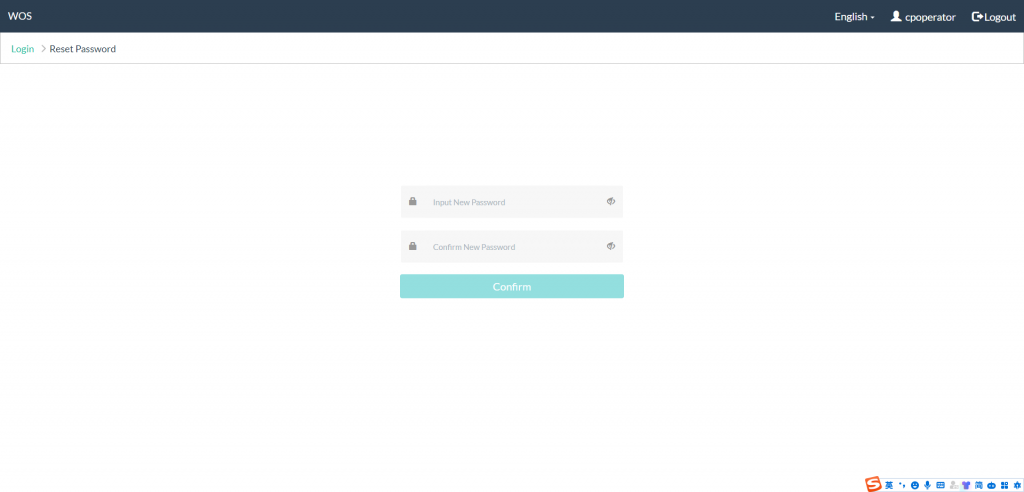

2.The login is successful, but you will be prompted to change your password. Please follow the instructions to change your password and then log in again.

reset the password and re-login by using new password.

Releasing Time: 2023.08.07

New Feature:

【Inbound】

When user receive product via WOS4(both receive first then putaway, and receive and putaway mode). Then the system user can scan either Location or Sub-Location to putway the product

Note:

If Location is scanned, follow the current system logic to generate inventory

If Sub-Location is scanned, system should record both Sub-Location and Location for the generated inventory

When user create order via excel or API and the relocation is input

if Location is set to relocation, follow the current system logic to generate inventory

If Sub-Location is also set, system should record both Sub-Location and Location for the generated inventory

Note: inbound part detail page display the Sub-Location. Please download the latest Inbound Template file.

【Outbound】

When user picking for outbound,

(1) if the allocated inventory with Sub-Location, then:

1) the system should display the Sub-Location for user

2) the user can scan Sub-Location during picking( Limit the outbound with sub-location to scan only sub-location during picking)

(2) if the allocated inventory without Sub-Location, then follow current logic to do picking

【 Inventory Update】

The system support user update Sub-Location via inventory update function

【 Inventory Movement】

If IM by pallet, should set the Sub-Location as null, and remind user to record Sub-Location via Inventory Update.

If IM by part, should support record latest Sub-Location during IM.

Support to use MXIC txt to create outbound booking via upload txt. The customer is specified.

【Created Shipping Job】

User can access Shimadzu Shipping module and create new shipping jobs. UI provide SO order search to select orders to create a job (not including completed and cancelled status orders). Support to create one job for one customer.

【Shipping Job Detail】

After entering one shipping job detail, user can see

ShippingJob No, Customer, Created By, Created Date, Status, Completed By, Completed Date, SO Order. User should select ‘Assign’ and other necessary info and save the job.

User can remove the orders from shipping job.

【Shipping Job Action】

Assign Shipping:

User can assign shipping when shipping job status is ‘In Queue’ and the selected order status is ‘Ready to Ship’. After assign successfully, the job status is ‘Ready to Sorted’

Cancel:

User can cancel shipping job when job status is ‘In Queue’ or ‘Ready to Sorted’. After cancel successfully, the job status is ‘Cancelled’.

Confirm:

User can confirm job which status is ‘Sorted’. After confirm successfully, the job status is ‘Completed’.

【Print Shipping List】

User can print shipping list which job status is ‘Ready to Sorted’, ‘Sorting’, ‘Partially Sorted’, ‘Sorteded’, ‘Completed’. The format is xlsx.

【Batch operate Shipping Job】

System support to batch operate shipping job for ‘Assign Shipping’, ‘Print Shipping List’, ‘Confirm’

【Task Summary】

On Dashboard, task summary adds below link:

Shimadzu Shipping In Queue

Shimadzu Shipping Ready to Sort

Shimadzu Shipping Sorting

Shimadzu Shipping Sorted

Provide Sort to Ship module on Shimadzu APP.

User can see the job list which job status is ‘Ready to Sort’, ‘Partial Sort’, ‘Sorted’. User can scan Shipping job No or PltRefNo to find the job.

When the job is operating, the job status is ‘Sorting’. When user begins to sort to ship, APP shows ShippingJob No, Delivery Date, Already loaded, Not yet loaded, and All Pallet(PleRefNo, Destination), OP can input Driver, Driver Phone, Car Plate Number, and Remark. User should scan PltRefNo to validate if it belongs to this job. User can partially done for some pallets. After all pallets are scanned, the job status is ‘Sorted’.

Releasing Time: 2023.06.29

New Feature:

Order Report

Inventory Report

Pick List Report

Inbound Receive Report

Movement Report

Packing Report

Shimadzu Order Report

Inventory Report in favor of Serial No

if order contains multiple Serial No,Serial No can be displayed by wrapping lines when print report.(include above report)

noted:Refer to the format of the picture on the right”

1>When user login wos4 and enters the Outbound order details page to view the data in the Criteria

2>When user create the outbound order by WOS UI for bundle part which has Bundle setting like Bundle No= BN001 —>SKU=SKU001, SKU=SKU002 ;

Then WOS4 do not convent value and keep the PartNo as BN001 before click the ‘generate picklist’ button.

When User click the ‘generate picklist’ button for this order

Then the partNo convented value SKU001, SKU002 and the ‘Belongs to Bundle PartNo’ is the bundle part value BN001 for this part.

When user create the outbound order for a bundle part which has Bundle setting and the have the catalog for the part like Bundle No = BN001 —>SKU = SKU001, UPC = PN001;SKU = SKU002, UPC = PN002 ;

Then WOS4 do not convent value and keep the PartNo as BN001 before click the ‘generate picklist’ button.

When User click the ‘generate picklist’ button for this order

Then the partNo convented value PN001, PN002 and the ‘Belongs to Bundle PartNo’ is the bundle part value BN001 and the ‘SKU No’ column display the sku value SKU001, SKU002 for this part.

3>When user create the outbound order by upload Excel Template/API for bundle part which has Bundle setting like Bundle No = BN001 —>SKU=SKU001, SKU=SKU002 ;

Then the partNo convented value SKU001, SKU002 and the ‘Belongs to Bundle PartNo’ is the bundle part value BN001 for this part.

When user create the outbound order for bundle part which has Bundle setting and have the catalog for the part like Bundle No = BN001 —>SKU = SKU001, UPC = PN001;SKU = SKU002, UPC = PN002 ;

Then the partNo convented value PN001, PN002 and the ‘Belongs to Bundle PartNo’ is the bundle part value BN001 and the ‘SKU No’ column display the sku value SKU001, SKU002 for this part.

1.shopline bundle quantity will mapping to wos4 reference1

2.if reference1 is int(正整数)

2.1 在packing模块打印packing slip时,如果pack qty/reference1 整除,packing slip上qty=pack qty/reference1

2.2 在packing模块打印packing slip时,如果pack qty/reference1 不整除,打印packing slip时,系统会提示对应的partNo不能整除

3.if reference1 is not int(正整数),在packing模块打印packing slip时,packing slip上qty=pack qty

ULPVG(上海仓)good receive模块收货模式默认为”收货并且上架“(Receive and put away),自动打印默认为”不打印”(No Print)

【Create outbound booking by UI 】

Outbound Order 通过UI创建时

Outbound -> Order Info页面 -> Reference Info 会显示Order Volume字段让用户填写;

Order Volume字段为正数,最多可精确到小数点后五位;

若用户填写的值不在系统规定范围内,系统会给予相应的提示。

【Create outbound booking by Excel 】

Outbound Order 通过Excel template 创建时

Outbound template中 Order Info会显示Order Volume字段让用户填写;

Order Volume字段为正数,最多可精确到小数点后五位;

若用户填写的值不在系统规定范围内,系统会给予相应的提示。

system can print inventory sheet report successful when use shimadzu si template upload to system

Releasing Time: 2023.04.26

New Feature:

1.UI will show courier service in outbound order list

2.user can query order by courier service in Order Search->Criteria->Advanced Search

3.query support fuzzy search

When user enter WOS and choose language is Chinese

Then user can see the buttons,columns,messages is Chinese in all the modules.

system support HS Code is 6 digits to print label

system support release si order with order service is ‘EFC Return’

User can choose customer at Good Receive module to display In Queue & Arrival Received si order list to select both by pallet or normal mode.

【Add CBM Per Part / Kg Per Part,Total Part CBM / Total Part Wt columns in Inbound Receive Report / Inventory Report / Inventory Report in favor of Serial No】

1>For Inbound Receive Report / Inventory Report / Inventory Report in favor of Serial No in Report module, the Avail Cols should have CBM Per Part / Kg Per Part ,Total Part CBM / Total Part Wt inside for users to choose

2>When user selects CBM Per Part / Kg Per Part ,Total Part CBM / Total Part Wt to Sels Cols then print Inbound Receive Report / Inventory Report / Inventory Report in favor of Serial No, they should show in the reports

3>When user set report profile or set schdule report include above columns for Inbound Receive Report / Inventory Report / Inventory Report in favor of Serial No ,

they should show in the report

Note:

Total Part CBM and Total Part Wt in Inbound Receive report:

Total Part CBM represents the total CBM of the same Parts in the same batch in SI

Total Part Wt represents the total Weight of the same Parts in the same batch in SI

Total Part CBM and Total Part Wt in Inventory report / Inventory Report in favor of Serial No:

Total Part CBM represents the total CBM of the inventory of the same Parts in the same batch

Total Part Wt represents the total Weight of the inventory of the same Parts in the same batch

【Move Norm Wt and Norm Vol coulmns from Sel Cols to Avail Cols in Inventory Report / Inventory Report in favor of Serial No】

1>For Inventory Report / Inventory Report in favor of Serial No in Report module, the Avail Cols should have Norm Wt and Norm Vol inside

2>When user selects Norm Wt and Norm Vol to Sels Cols then print Inventory Report / Inventory Report in favor of Serial No, they should show in the reports

3>When user set report profile or set schdule report include Norm Wt and Norm Vol for Inventory Report / Inventory Report in favor of Serial No ,

they should show in the report

1>when Sales Platform is SL_SP_EN,user can print packing slip in packing modelue and the packing slip language is English

2>when Sales Platform is SL_SP_CN,user can print packing slip in packing modelue and the packing slip language is Chinese

3>when Sales Platform not SL_SP_CN/SL_SP_EN,user can print packing slip in packing modelue and the packing slip language is Chinese and English

1>When user process inv update in Part Detail page of Inv Update model,

Then Part Detail list diaplays CBM Per Part / New CBM Per Part / Kg Per Part / New Kg Per Part column;

2>When user was under Part Detail list of Inv Update model,

If the CBM Per Part / Kg Per Part has a value,

Then the system displays the corresponding value;

If the CBM Per Part / Kg Per Part has not a value,

Then the system displays null value,

And Then the CBM Per Part / Kg Per Part column is not editable;

3>If user was under Part Detail list of Inv Update model,

When he wants to update the value of CBM Per Part / Kg Per Part,

Then he can edit the value of New CBM Per Part / New Kg Per Part column;

4>When user edited the value of New CBM Per Part / New Kg Per Part column,

Then system save the value of New CBM Per Part / New Kg Per Part,

And the update the value to inventory;

5>When user process inv update in Part Detail page of Inv Update model,

Then Part Detail list not diaplay the Normal Vol / Normal Wt / New Normal Vol / New Normal Wt coulmn.”

1> Add one select box Items Per Search that can search ALL/500 datas at Criteria->Advanced Search of Outbound Order Search page

2> The select box named “Items Per Search” and the default option for this box is ALL, “Items Per Search” Chinese translation is “每次搜索的订单数”.

3>User should input the corresponding Criteria other than “Items Per Search” and the “Items Per Search” option for this box is 500,

if user click search and searched for orders more than 500,

then system will automatically display the top 500 outbound orders in the search results;

if user click search and searched for orders less than 500,

then system will automatically display all outbound orders in the search results.

4>if user only input “Items Per Search” option for this box is 500,

the system will reminder me with message as: “Items Per Search” must be used in combination with other Criteria. Please input at least one criteria other than “Items Per Search”

And the Chinese translation is “每次搜索的订单数” 需跟其他的搜索条件组合使用,请填写除 “每次搜索的订单数” 之外的其他条件。

1>Inbound Order 通过UI创建时

Inbound -> Order Part页面会显示CBM Per Part和Kg Per Part字段让用户填写;

CBM Per Part和Kg Per Part字段为正数,最多可精确到小数点后五位(多于五位的会四舍五入保留五位);

若用户填写的值不在系统规定范围内,系统会给予相应的提示:”CBM Per Part [XXX] is invalid. It must be positive real no.Part No: XXX” or “Kg Per Part [XXX] is invalid. It must be positive real no. Part No: XXX”。

2>Inbound Order 通过Excel template 创建时,

inbound template中 Part Info ->Order Part Additional Info会添加CBM Per Part和Kg Per Part字段让用户填写;

CBM Per Part和Kg Per Part字段为正数,最多可精确到小数点后五位(多于五位的会四舍五入保留五位);

若用户填写的值不在系统规定范围内,系统需给予相应的提示,提示可参照CBM per Carton/Kg per Carton处的提示。

3>如果通过UI/Excel template/API创建的inbound中有新的Part,且CBM Per Part/Kg Per Part字段填了相应的值。

系统会将CBM Per Part的值Mapping到WMS Part Profile中的Part CBM;将Kg Per Part的值Mapping到WMS Part Profile中的Gross Weight。

4>如果通过UI/Excel template/API创建的inbound中没有新的Part,

系统会判断当前inbound order的客人是否设置了Quotation,且Quotation中是否设置了STO是以CBM去收费的;

4.1>如果设置了,系统会判断inbound order中Part的CBM Per Part是否有值;

如果有值,那么WMS计算billing的时候,则取inbound order中CBM Per Part的值,若其他字段都符合系统的创建规则,那么inbound order可以创建成功。

如果没有值,那么系统会判断inbound order中的Part,在WMS的Part Profile中Part CBM是否有值;

如果在WMS的Part Profile中Part CBM有值的话,

那么WMS计算billing的时候,则取WMS Part Profile中Part CBM的值,若其他字段都符合系统的创建规则,那么inbound order可以创建成功。

如果在WMS的Part Profile中Part CBM没有值的话,

那么系统会提示用户:CBM per Part is Mandatory for storage calculation, please provide correct data of cbmPerPart for Part XXX under Inbound Order then continue.,且该inbound order不可以创建成功。

4.2>如果没有设置的话,系统会忽略CBM Per Part的检测,若其他字段都符合系统的创建规则,那么inbound order可以创建成功。

【Inbound order】

Total Qty Book/总预订数量(订单内各商品Qty Book的总和)

Total Qty /总数量(订单内各商品实收数量Qty的总和)

1> 用户登录到wos4并且打开了Inbound order模块

When 用户查看Header Profile

Then 系统会显示Total Qty Book,Total Qty的column及正确的数据供用户查看

2>用户登录到wos4并且进入到Inbound order详情页面中

When 用户在Order Part查看数据

Then 系统会在Total Item后面显示Total Qty Book,Total Qty的column及正确的数据供用户查看

【Outbound order】

Total Request Qty/总请求数量(订单内各商品Request Qty的总和)

1> 用户登录到wos4并且打开了Outbound order模块

When 用户查看Header Profile

Then 系统会显示Total Request Qty的column及正确的数据供用户查看

2>用户登录到wos4并且进入到Outbound order详情页面中

When 用户在Criteria查看数据

Then 系统会在Total Item后面显示Total Request Qty的column及正确的数据供用户查看

【Order Report】

1>用户登录到wos4中打印Order Report

When 用户选择需要的字段

Then 系统在Avail Cols显示字段Total Request Qty供用户选择

When user access report module to print the order report.

And user can click the ‘partNo’ in Sel Cols

Then the system will pop up the prompt and ask user: need to remove all information from the Part layer?.OK Cancel

1>When user click the ‘ok’ for the partNo

Then all the column of part layer will be remove from the Sel Cols and back to Avail Cols.

When user click print report this time

Then the order report will remove all the column about part layer in the order report.

2>When user click the ‘cancel’ for remove the partNo layer

Then only the column of partNo will be remove from the Sel Cols and back to Avail Cols.

When user click print report this time

Then the order report will only remove partNo column in the order report.

When user access order report to print the order report.

And user can click the CartonNo’ in Sel Cols

Then the system will pop up the prompt and ask user: need to remove all information from the carton layer?.OK Cancel

1>When user click the ‘ok’ for remove the cartonNo layer

Then all the column of carton layer will be remove from the Sel Cols and back to Avail Cols.

When user click print report this time

Then the order report will remove all the column about carton layer in the order report.

2>When user click the ‘cancel’ for remove the cartonNo layer

Then only the column of carton No will be remove from the Sel Cols and back to Avail Cols.

When user click print report this time

Then the order report will still display the cartonNo column in the order report when there have some carton layer column in sel col.

Note:Because the carton layer column have to relate to cartonNo,so if the sel col have the carton layer column,then the order report will display the catton No column.

3>When user click the ‘ok’ for remove the partNo layer and click the ‘ok’ for remove the cartonNo layer

Then all the column of partNo layer and carton layer will be all remove from the Sel Cols and back to Avail Cols.

When user click print report this time

Then the order report will remove all the column about partNo layer and carton layer,it means one order only have one line in the order report.

User can choose multiple Shimadzu_Original_Files to create one SI order with Choose Template Type as Shimadzu via excel upload.

Releasing Time: 2023.03.14

New Feature:

When outbound order is synced from 奇门 to WOS4,courier Service = YTO/圆通,opration the order to “Packing”,click Print Shipping Label in Packing module,a corresponding Courier Bill Label will be printed out automatically

Now,MUJI Packing slip bardCode will be replace QR Code. detail for right picture

When scan the wrong Part No. or Serial No during Packing,

the input box will show a red alert and an error tone;

and will keep the wrong Part No./Serial No. in the input box for OP to check.

1.In WOS4 Outbound Packing module, the input colume show like below

Order No/Ecommence Order No/Batch No/Courier Bill No

2.When scan/input Courier Bill No. and click ‘->’

Then system can query out the corresponding record from outbound order

1>if can’t find related record:

Then system shows reminder message like

“Order @number cannot found. please check it”

“订单 @number 找不到. 请检查”

2> if find one unique record:

Then system show the order detail to UI page

3>if find multiple records, such as an order’s Ecommerce Order No is equal with the input one, another order’s courier bill no is equal wth the input one

Then system can show all the matched record as a list to let user choose one to show the order detail to UI page

System still can support to query record by Order No, Ecommerce Order No, Batch No without change.

1.In ULPVG,when user search the order which push by the 3-party platform with 菜鸟courier in outbound order module

Then system will generate the courier bill No for the order in Allocated status,user can see the courier bill no of the order in orderInfo page.

2.In ULPVG,when user input the orderNo/Ecom orderNo to search an order in picking

Then user can see the printer print out the 菜鸟courier bill label.

3.In ULPVG,when user choose the customer to pick multiple orders and click “search” in picking

Then user can see the printer print out the courier bill label for the order which courier is 菜鸟

And user can see the printer print out the Ecom orderNo label for the order which courier isn’t 菜鸟

4.When user choose the order which courier is 菜鸟 and click “print” in picking-print page

Then user can see the printer print out the 菜鸟courier bill label.

When the “訂單總額” of the MUJI packing slip is 0

Then can successfully print out the MUJI packing slip.

New Feature:

1.Avail Cols should have Qty Unit inside for users to choose

2. updates a profile or create a new profile and adds Qty Unit column to Sel Cols

3.system send or print order report

Then all column in Sel Cols include Qty Unit column should be in the report

1.Avail Cols should have No Of Pkg & Order Gross Weight inside for users to choose

2. updates a profile or create a new profile and adds No Of Pkg & Order Gross Weight column to Sel Cols

3.system send or print order report

Then all column in Sel Cols include No Of Pkg & Order Gross Weight column should be in the report

New Feature: